An industrial gear pump is one of the most reliable components used across various industries, from chemical processing to food manufacturing. Known for their efficiency and ability to handle different viscosities, these pumps play a vital role in keeping operations smooth. While they are designed for durability, their performance and longevity depend heavily on proper care and maintenance.

This comprehensive guide will explore the best practices for maintaining an industrial gear pump, common issues to watch out for, and strategies to ensure that high-pressure gear pumps deliver optimal performance for years to come.

Understanding the Importance of Maintenance

Industrial equipment undergoes continuous stress, and a pump is no exception. The consistent flow of fluids, combined with exposure to pressure, heat, and sometimes corrosive materials, puts strain on the components. Without proper maintenance, wear and tear can lead to reduced efficiency, frequent breakdowns, and costly replacements.

Routine maintenance not only extends the lifespan of an industrial gear pump but also minimizes downtime, prevents leakage, and ensures energy efficiency. By investing time in care, industries can save significantly on repairs and unexpected shutdowns.

Key Components That Require Attention

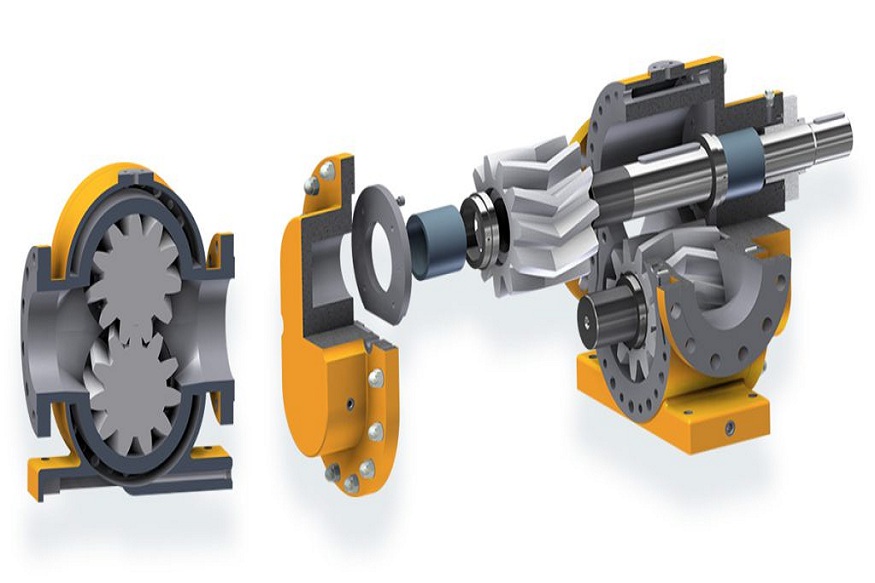

An industrial gear pump consists of several critical parts that need regular inspection. Paying close attention to these areas can prevent premature failures:

- Gears – The heart of the pump, responsible for moving fluid. Worn or misaligned gears reduce efficiency.

- Bearings – These support the shafts and must be checked for wear or overheating.

- Seals – Essential for preventing leaks, seals are prone to wear from high pressure and abrasive fluids.

- Casing – Regular inspection ensures there are no cracks or damage from pressure variations.

- Lubrication system – Proper lubrication reduces friction and prevents overheating of moving components.

By focusing on these areas, operators can ensure that both standard and high-pressure gear pumps run smoothly.

Best Practices for Industrial Gear Pump Maintenance

1. Establish a Regular Inspection Schedule

Consistency is the foundation of pump maintenance. Setting a daily, weekly, and monthly checklist ensures that no component is overlooked. Daily checks can include monitoring temperature and pressure readings, while monthly inspections should involve detailed evaluations of gears, seals, and lubrication levels.

2. Monitor Fluid Quality

The type and quality of fluid being pumped have a direct impact on the pump’s health. Fluids with high levels of contamination or abrasiveness can accelerate wear on gears and seals. Installing filters and ensuring fluids meet required cleanliness standards can significantly extend the pump’s lifespan.

3. Maintain Proper Lubrication

Lubrication plays a crucial role in minimizing friction and wear. Operators should always ensure that the pump has the correct type and amount of lubricant.

4. Check for Unusual Noises and Vibrations

Excessive vibration may point to misalignment, bearing wear, or gear damage. Early detection allows for corrective measures before the issue becomes critical.

5. Ensure Correct Alignment

Misalignment of the pump with its motor can lead to excessive stress on bearings and gears. Using precision alignment tools during installation and regular checks helps maintain smooth operation and reduces mechanical strain.

6. Keep Operating Conditions Within Limits

Every industrial gear pump is designed to operate within specific temperature and pressure ranges. Running it beyond these limits can shorten its life significantly. Operators should consistently monitor operating conditions and avoid overloading high-pressure gear pumps beyond their rated capacity.

7. Replace Worn Parts Promptly

Delaying replacement of damaged or worn components often leads to bigger failures. Keeping spare seals, bearings, and gaskets on hand ensures quick repairs and prevents unnecessary downtime.

Common Problems and How to Solve Them

- Reduced Flow – Can result from clogged filters, worn gears, or fluid viscosity changes. Regular cleaning and gear inspections resolve the issue.

- Overheating – Usually linked to inadequate lubrication or excessive pressure. Ensuring proper lubrication and operating conditions keeps the temperature under control.

- Unusual Noise – May indicate cavitation or gear misalignment. Checking fluid levels, gear condition, and alignment can address the problem.

Extending the Lifespan of High-Pressure Gear Pumps

High-pressure gear pumps face more demanding conditions than standard pumps. To maximize their service life, additional precautions should be taken:

- Use high-quality fluids designed to withstand elevated pressure.

- Regularly inspect seals, as they are more prone to wear in high-pressure environments.

- Monitor discharge pressure to avoid running the pump beyond its rated capacity.

- Ensure proper cooling systems are in place to prevent overheating under heavy loads.

By following these practices, industries can significantly extend the life of their high-pressure gear pumps while maintaining peak performance.

The Role of Training and Skilled Operators

Even the best maintenance plan will fall short if operators lack the knowledge to carry it out effectively. Training staff on proper pump operation, early warning signs of issues, and maintenance techniques is essential. Skilled operators not only prevent damage but also ensure the pump operates at its highest efficiency.

Benefits of Preventive Maintenance

Implementing preventive maintenance offers several long-term benefits:

- Cost Savings – Reduces the need for expensive repairs and replacements.

- Reliability – Ensures consistent operation, minimizing production downtime.

- Efficiency – Well-maintained pumps consume less energy and deliver better performance.

- Safety – Prevents accidents caused by leaks, overheating, or sudden failures.

An industrial gear pump is a valuable asset in any manufacturing or processing plant. Its performance and lifespan are directly linked to how well it is maintained. By adopting a proactive approach that includes regular inspections, lubrication, monitoring of fluid quality, and timely part replacement, industries can maximize efficiency and minimize costly downtime.

For high-pressure gear pumps, additional care must be taken due to the intense conditions they face. With consistent maintenance and skilled operation, these pumps can deliver reliable service for years, making them an indispensable part of modern industry.